5L open top plastic pail paint filling line

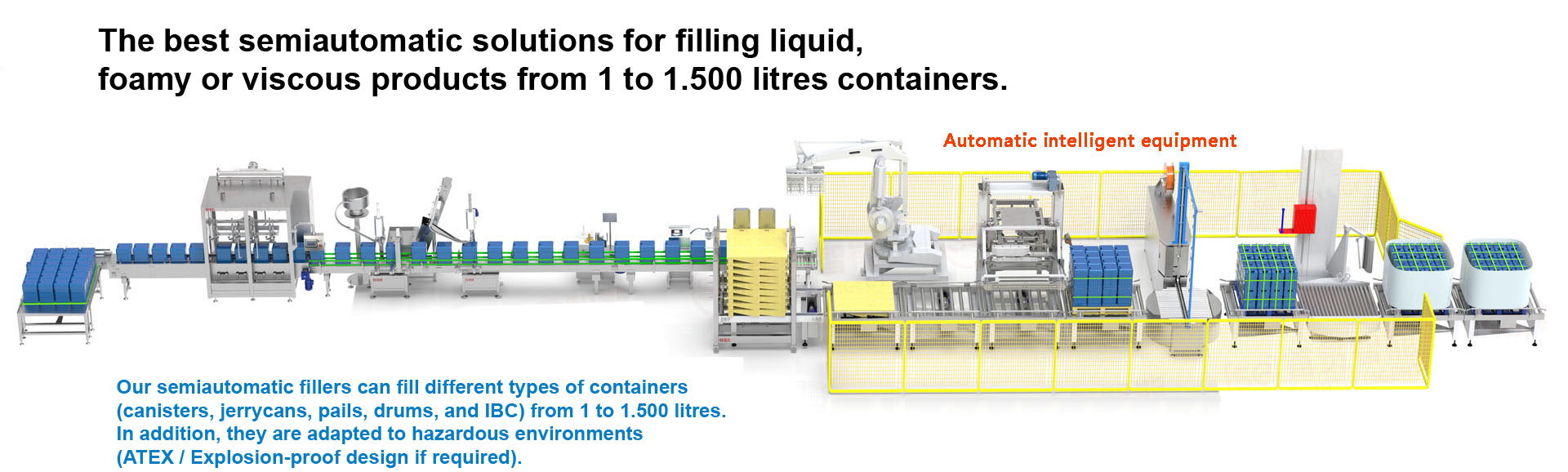

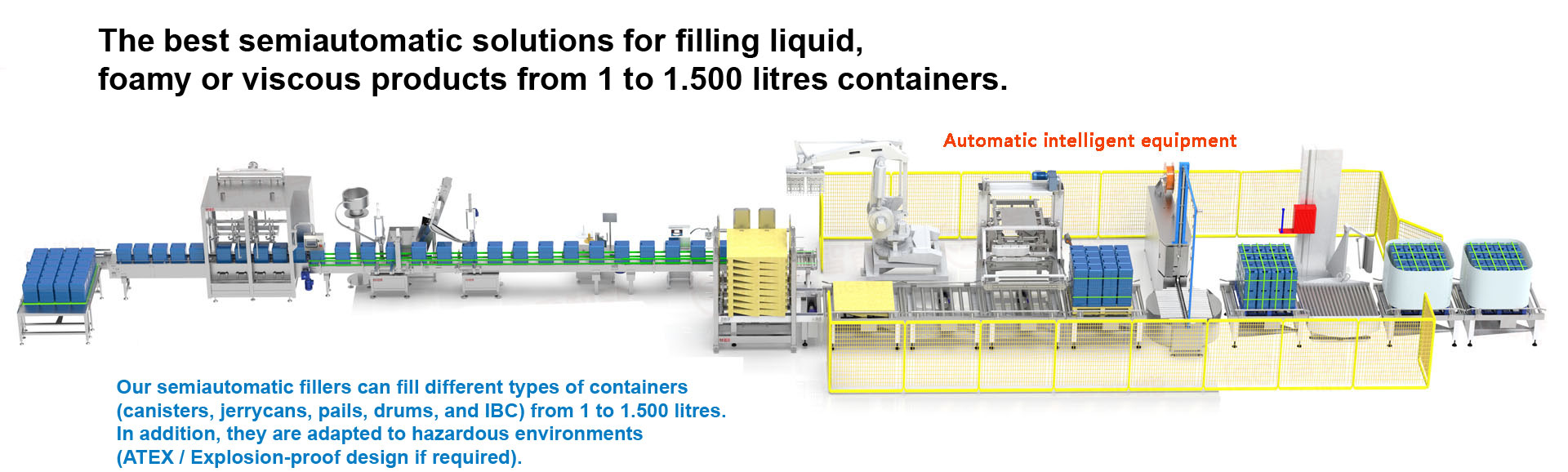

GFM-5 model is used to fill paint, coating, food additivies, solvent etc into 1L-5L can, pail, bottles automatic filling line.

GFM-5 Liquid filling machine, filling machine, filling system, high degree of automation, can avoid the material overflow, to prevent the material itself to the environment pollution, thus effectively labor protection to operators.Liquid filling system stable and reliable work, convenient operation, accurate weighing and weight data by instrument output to a computer and other external devices.Food processing, medicine, pharmaceutical and chemical industry, it is often necessary to product structure of the surface is bright and clean, anti-rust, anti-corrosion, explosion-proof, even Shanghai guang device specially designed for such applications to produce a anti-corrosion type filling machine, filling machine filling machine, filling machine, food grade and explosion-proof type filling machine, filling machine.

Liquid filling equipment of measurement, it is set the heavy type metering mode to the liquid products, realize automatic speed control, automatic filling of special equipment, the equipment is suitable for petrochemical industry, dye, grease, paint and other industries, especially to be toxic, strong corrosion, inflammable, explosive, volatile, easy oxidation, coagulation, easy to crystallization of all sorts of chemical material such as filling.

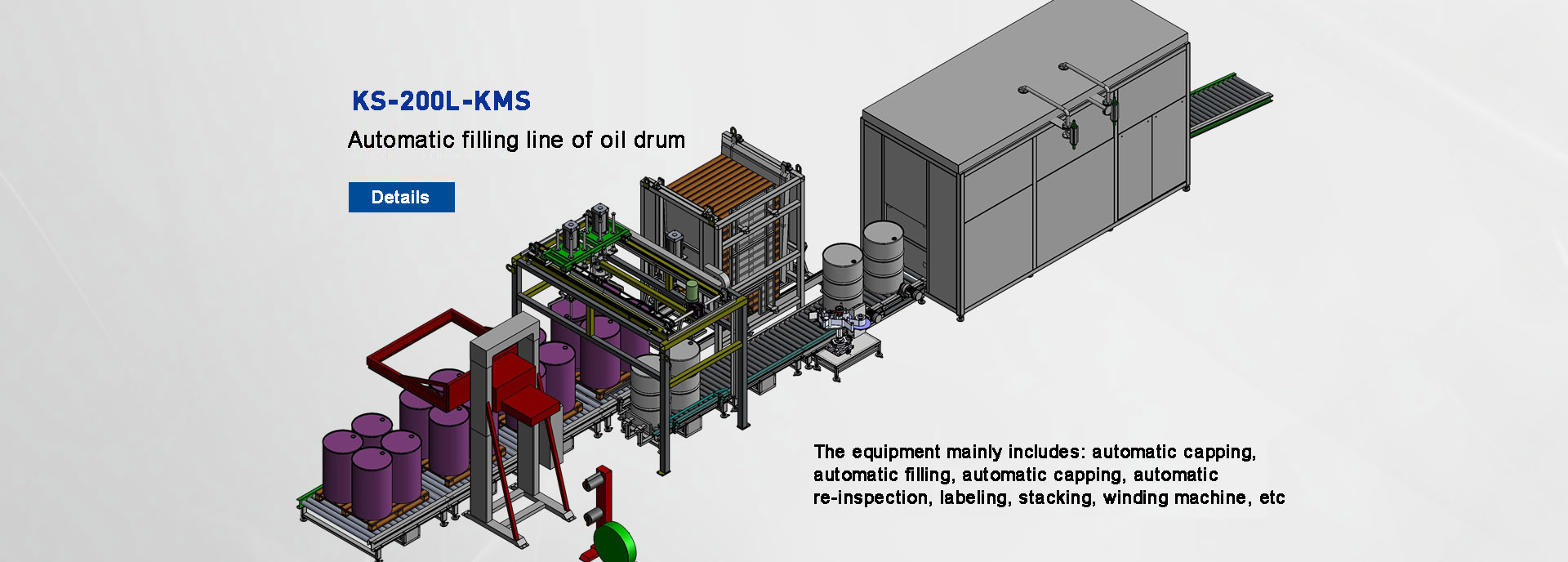

20 l closed templet explosion-proof filling machine bottom pouring type can realize automatic machine is special equipment for liquid products, suitable for low corrosive medium heavy machine, homework, just put the container at the input end of the transmission system, the rest of the operating procedure (open cover, filling and closing cover) are completed automatically.

Process: artificial empty barrel on barrel - automatic conveying bucket - pull cover - automatic filling measurement - shut automatically cover - automatic weighing hopper

Filling capacity not less than 500 barrels per hour

Nitrogen filled function

Nitrogen filled function in the process of filling, the use of nitrogen and the inert gas is used to cut off filling material and air reacts, application nitrogen filled function materials mainly include the phenol, epoxy propane, butylene glycol, acrylic acid, aniline, tetrahydrofuran, etc.

Heat tracing function

To prevent solidification filling material, the use of thermal insulation function, is advantageous to the filling process, the application tracing function materials mainly include acetic acid ethyl ester, TDI, adjacent nitro toluene, ether, phenol, acrylate, methyl ethyl ketone and other materials under normal temperature crystallization.

Scavenging function

After filling, if the remaining material is not clear for a long time could be cured or corrosive filling equipment, so you need to use at the end of the filling purging function, the pipeline purging clean surplus materials;Filling equipment replacement material, also need to be purging before change, in particular, corrosive, flammable, explosive materials, especially under the condition of two kinds of material to produce chemical reaction, can reduce the risk of scavenging function.

Bottom infuse with applicable types: in the filling process of foam, easy to produce static material, it is recommended to use the bottom pouring way, such as phenol, butylene glycol, propylene oxide, alcohol ether, etc.

CONTACT US

Skype: fayfaywang1027

QQ: 429682794

Whatsapp: 008618016442021

E-mail: glzoncn@163.com

https://glzon.en.alibaba.com/

cel: +0086 18016442021